Pitot Tube and Manometer Method

Pitot tubes are a very old but very accurate tool used to measure flow. A pitot tube is essentially a narrow copper tube with a series of holes in it that is inserted into the discharge pipe, perpendicular to the direction of flow. The holes measure the pressure differential between the side of the tube that is facing toward the flow (discharge) and the side that is facing away from the flow (static). This differential is transferred to a Manometer. A manometer consists of two vertical glass tubes with a numbered measurement rod in the middle. When the pitot tube is inserted and the water is flowing through the discharge pipe, the glass tubes fill with water. Each tube measures one side of the pitot tube, so the water columns are not equal. The difference between the two water columns is measured using the rod in the middle. Prior to inserting the pitot tube, the Testman will measure the inside diameter of the pipe and use that number to identify the area of the pipe. The area of the pipe will then be multiplied by the manometer measurement, which will give us the flow in gallons per minute. For instance, if the inside diameter of the pipe is 8”, the area of the pipe would be 50.265. If the manometer measurement is 14, you would multiply 14 by 50.265, which would give you a flow of 704gpm. The benefit of using a pitot tube and manometer is that you can see the water in the tubes which can help you identify turbulence and other issues that might affect the flow measurements. Pitot tubes require a threaded hole in the discharge piping. If possible, the Testman will utilize an existing hole. If one is not available, the Testman will drill and tap a new hole in the piping, then thread in a plug when testing is complete. Most piping configurations do not allow for a perfect flow reading location but when available, the pitot tube will be placed 8-10 pipe diameters downstream and 2-3 pipe diameters upstream from any valving or curvature on the pipe. This location will provide the least amount of turbulence in the flow reading.

Ultrasonic Method

When there is no existing hole in the discharge piping and the Testman cannot drill and tap a new hole, the Testman can measure the flow by using an ultrasonic flow measurement tool called a Flexim. The Testman will input a series of parameters into the Flexim, including pipe material, the outside diameter and wall thickness, water temperature, and- if applicablethe type and thickness of the liner in the pipe. Once the parameters are set, the Testman will connect a set of transducers to the pipe and adjust them to find the best signal. Once set, the transducers will send a signal to one-another to measure the flow. The benefit to this method is that you can change the transducers closer or further apart, on the same side of the pipe or on opposite sides of the pipe, to dial in the signal for the best possible measurement. This method can be used on pipe diameters as small as 2” and upwards of 4’. As with the pitot tube, the ultrasonic flow meter will be placed in a location that provides the least amount of turbulence possibility. Both the pitot tube and Flexim offer flow measurement accuracy to within half a percent. The Testman will decide what the best method for flow measurement is upon inspection of the system.

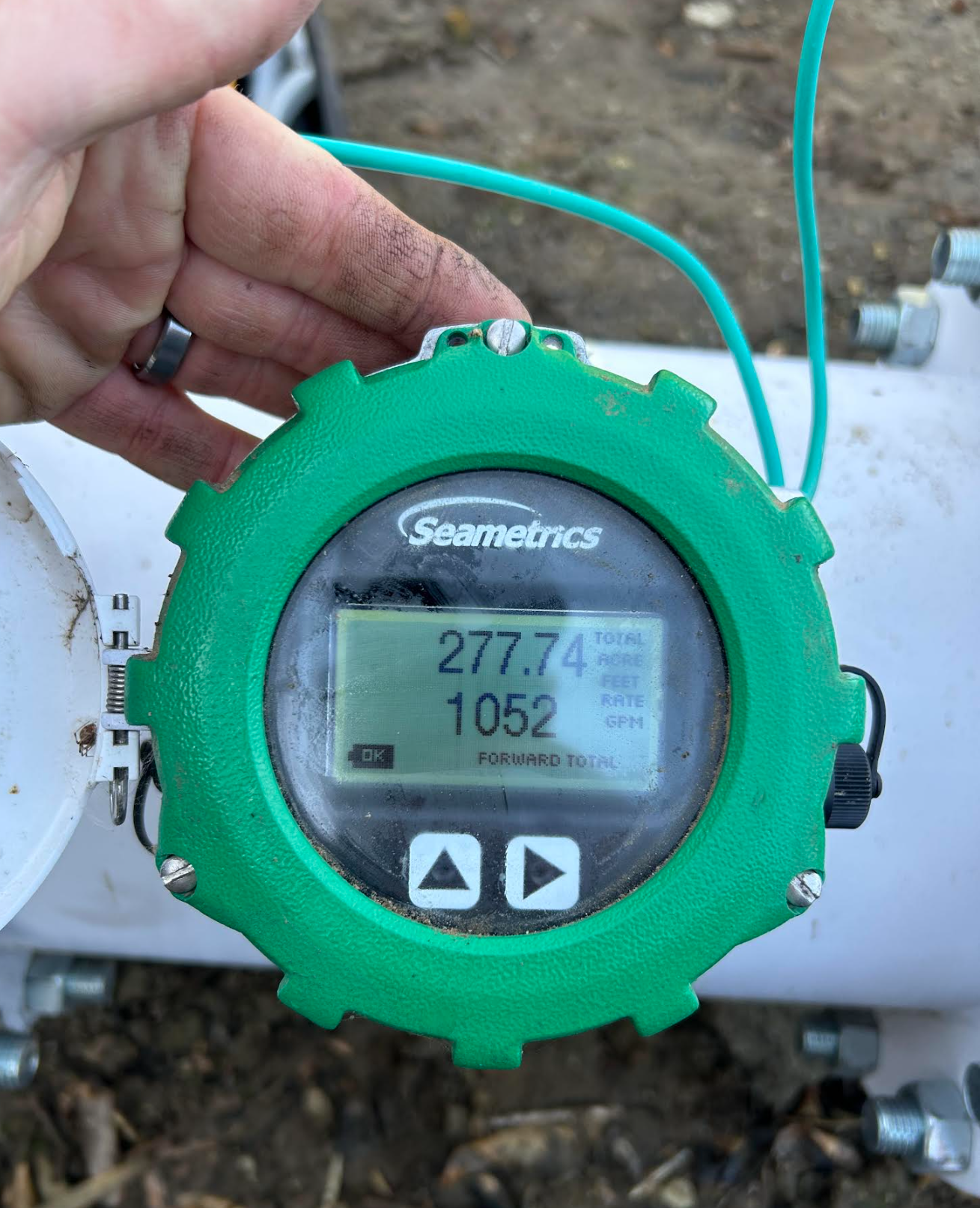

Verifying the Customer’s Flow

The Testman will record the reading on the customer’s flow meter and compare it to the measurement obtained using our equipment. If the customer’s flow meter is analog, the Testman will record how long it takes for the meter dial to complete a certain amount of revolutions. For instance, if the meter measures water in gallons x 100, the Testman can time how long it takes to register 100 gallons and use a formula to convert that number to gallons per minute. A sample of that formula would be the meter’s multiplier / time taken to complete a certain amount of revolutions x 60= GPM. The Testman would then compare their flow with flow obtained from the customer’s meter, then provide the customer with how high or low their meter is registering as a percentage. Example: Testman uses the Flexim to measure a flow of 1082gpm, the customers meter is registering 1052gpm. 1082gpm – 1052gpm = difference between the two meters of 30gpm. 30gpm difference / 1082gpm = 0.0277. In this situation, the customer’s meter would be registering low by 2.8%.